Advantages of Selective Wave Soldering Equipment

ETA provides high quality wave soldering machine, lead-free wave solder machines, selective wave soldering machine, for SMT smart factory.

Selective wave soldering machine is a new wave soldering machine process developed mainly to meet the high-quality assembly requirements of mixed products containing through-hole plug-in components. For communication systems, power systems, automotive electrical and electronic, aerospace, military equipment and other products that require high reliability and high precision, the PCB boards are often high-density double-sided boards and contain a certain amount of through-hole plug-in components. The reflow soldering technology and wave soldering technology can not meet its assembly requirements. In this case, selective soldering technology has emerged to realize the assembly of certain through-hole plug-in components or other high-precision components. It has separate solder joint parameters, which has little thermal shock to the PCB and flux. The advantages of low spray volume and strong welding reliability are gradually becoming an indispensable welding technology for complex PCBs.

Advantages of selective wave soldering equipment:

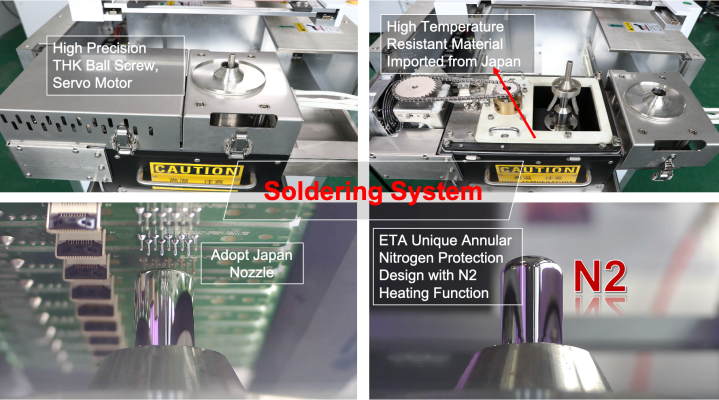

Advantage 1: stable quality, almost zero defects

Reason: closed-loop control of process parameters, full nitrogen filling in the welding area, good welding quality and hole filling rate can be obtained during welding.

Advantage 2: faster than hand welding and welding robots

Reason: Three separate working areas can work at the same time, multi-axis, double tin cylinders, and double sprays can move at the same time.

Advantage 3: Excellent no-clean process

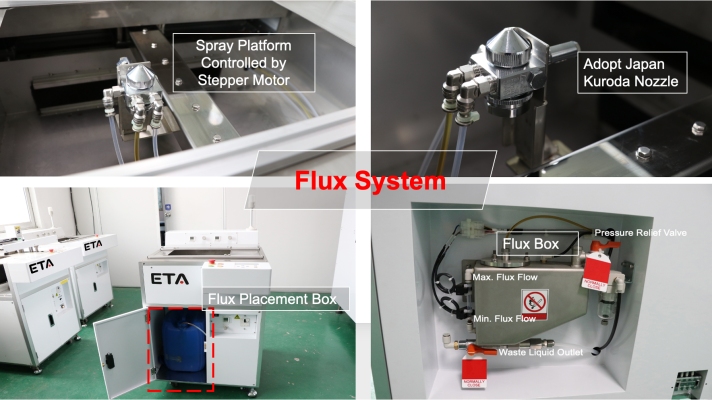

Reason: Selective soldering is only the selective spraying of flux for the points that need to be soldered, so the cleanliness of the circuit board is greatly improved, and the amount of ion pollution is greatly reduced.

Advantage 4: Precise preheating temperature control

Reason: A variety of heating methods, a variety of heating time control, the circuit board is not easy to bend and deform due to high temperature.

Advantage 5: strong process capability

Reason: Selective welding overcomes many welding areas that traditional wave soldering cannot overcome through the function of precise programming.

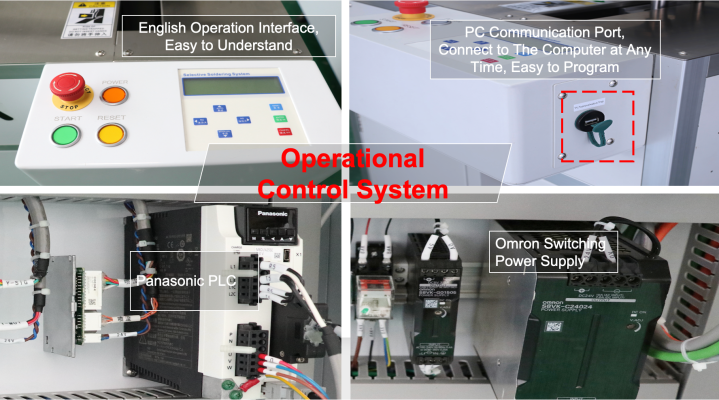

Advantage 6: Visualization of process parameters and welding process

The unique welding parameter traceability system and visual welding process design allow you to easily improve the welding quality and achieve refined quality management.

❙ Selective Wave Soldering Machine Video