Basic Description

With the same level of configuration as the I.C.T-450, but it has a less weight and lower power consumption due to shorter effective length.

Using different solder pot material, chain claw than the WS-450 and adopting manual spray fill flux system, it is a lower budget than the WS-450. What’s more, a maximum PCB width of 350mm can totally satisfy the common size of PCBs.

Spray nozzle driving by Servo motor will be guided speeding and frequency according to the PCB dimension. Using inverter for solder wave, it is easy to obtain energy that saved by independent driver and board sensor when PCB board is entering.

Feature

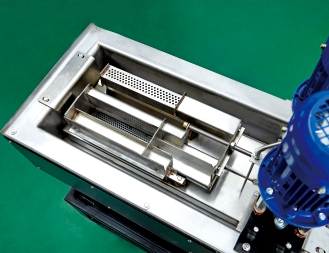

1. Wave Soldering Furnace System

- The wave soldering furnace is designed with the principle of towing welding to reduce the occurrence of air welding

- Tin wave fast and short distance spray tin spray, discharge the bubble

- Tin wave after a large and smooth spray of tin liquid, increase the contact area of tin liquid and parts foot, to prevent the phenomenon of air welding and continuous welding

- The first wave peak nozzle design uses hydrodynamics to produce columnar jet wave peak, reduce the surface tension of liquefied metal, solve the leakage welding of element and the welding shadow of SMD element

- Second smooth wave nozzles have no impulse design, which can adjust the welding area, flow rate and time

2. Automatic Flux Addition System

- The automatic flux addition system can reduce the waste caused by artificial flux.

3. Friendly Interface System

- Windows series control system, user-friendly interface with simply English and Chinese language alternative is selective, which is very convenient to operate.

- Enable the function of displaying various faults and automatically storing the alarm list.

Specification

| Model | WS-350 |

|---|---|

| Run Power | 7kw |

| Total Power | 21kw |

| Control Method | PC/Touch screen/Key board |

| Power | AC380V, 50 HZ, 3 phase |

| Spray System | |

| Drive Type | Step motor |

| Spray Pressure | 0.3-0.5MPa |

| Spray Wash | Auto wash |

| Flux Control | 0-100ml adjustable |

| Auto Fill Flux | Manual (Option Auto) |

| Exhaust | Top Exhaust |

| Ducting Dimension | 200mm (Diameter) |

| Preheater System | |

| Preheating Mode | Hot air |

| Preheating Zone number | 3 |

| Preheating Length | 1800mm |

| Preheating Temperature | Room temp - 200 Celsius degree |

| Warm Up Time | Approx. 15min |

| Conveyor System | |

| PCB Width | 50-350mm |

| PCB Direction | L to R/R to L |

| Conveyor Speed | 0-2000mm/min |

| Conveyor Angle | 3 degree - 7 degree |

| Conveyor Height | 750+20mm |

| PCB Height | Top 120mm, bottom 20mm |

| Speed Control | Frequency governor |

| Chain Claw | Double hook short titanium claw |

| Pot System | |

| Solder Pot Material | 316SUS (option:Titanium or nodular iron) |

| Solder Wave Driver | Motor driver |

| Solder Heater Type | External heating |

| Solder Warm Up Time | Approx. 120min |

| Pot Power | 13.5kw |

| Pot Temperature | Highest 320 Celsius degree |

| Pot Capacity | 350-400kg |

| Wave Motor Power | 1/2HPx2, 3p220VAC |

| Cooling System | |

| Cooling Method | Forced air cooling |

| Finger Cleaning System | Auto |

| Option | |

| Centre Support System | Option |

| UPS Protection System | Option |

| Top Pre-heater | Option |

| N2 System | Option |

| Dual-rail System | Option |

Keywords:

AutomatIC Vacuum Gluefilling Production SMT Line, Lead Free Reflow Oven With Temperature Testing, SMT PICk And Place Production Machine, Tape Feeder PICk And Place Machine, Tabletop LED PICk And Place Machine

Small SMT PICk And Place Machine, Best SMT PICk And Place Machine, LED Tubelight PICk And Place Machine, PCB Cleaner Lacquer Thinner, Mobile PCB Cleaner Liquid, Robot Vaccum Cleaner Hardware PCB, Cleaner PCB, PCB Alcohol Cleaner

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com