Off-line Selective Soldering Machine

Basic Description

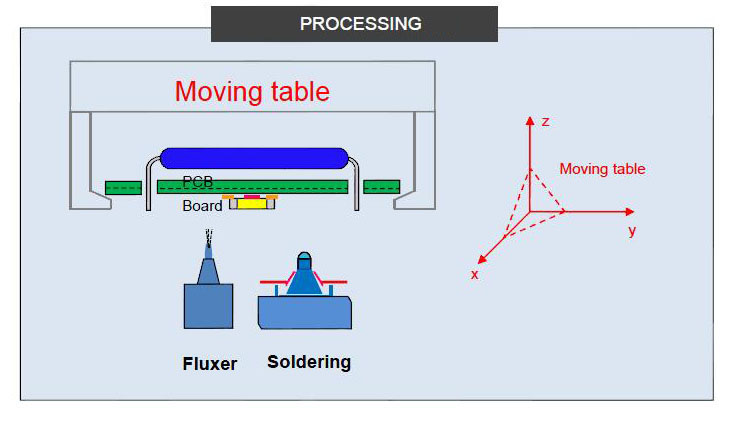

The machine integrates flux spraying and soldering. Besides, the solder pot is fixed, and the PCB board moves to realize soldering; Maximum PCB dimensions is 300 x 300 mm.

Small in occupation space and low in energy consumption, using manual placement and removal of boards. It is particularly suitable the products of NPI.

Feature

1. Conveyor System

- Lightweight motion platform design to increase the running speed while ensuring the rigidity of the platform.

- The XY axis adopts a combination of timing belt and guide rail, and the Z axis adopts a combination of screw and guide rail, which not only meets the accuracy requirements, but also greatly reduces the cost, and the speed is greatly improved.

- The mobile platform is equipped with a dust-proof plate to prevent dirt from dripping onto the ball screw

2.Spray Valve Part

- Atomization valve imported from Japan as standard.

- Optional piezoelectric ceramic injection valve made in Germany, suitable for flux with a solid content of less than 10%.

- The flux is stored by pressure irrigation to ensure a constant spray pressure and is not affected by the amount of flux.

3.Selective Tin Furnace Part

- Tin furnace temperature, nitrogen temperature, peak height, peak correction, etc. can be set by computer.

- The inner tank of the tin furnace is made of titanium alloy and has no leakage. External heating plate, even heat transfer.

- All tin furnaces are connected by quick connectors, so there is no need to re-wire when replacing the tin furnace.

- Nitrogen on-line heating device to ensure good of the tin furnace and reduce oxide production.

4.PCB Release Mechanism

- Manual board placing and picking.

- The universal fixture is integrated on the motion platform, which can place more types of PCB boards.

- Tin furnace with tin level alarm.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

SMT Assembly Line, Full AutomatIC SMT Line, Stencil Printer, SMT Stencil Printer Machine, SMD Oven, SMD Reflow, Solder DIPping Machine, SMT Chip Mounter Filter Element Cotton Swab, LED Placement Machine, Magnet Placement Machine, PCB AutomatIC Coating Machine, PCB Conaformal Coating Machine, PCB Coating Machine Dispensing, PCB AutomatIC Selective Coating Machine, PCB Laser Cutting Table Top Machine, High Frequency Plasma Cutting PCB Board, PCB V-Cut Machine Part, Soldering Robot For 5 Axis, Soldering Robot With Desktop For 5-Axis