Basic Description

The model consists of flux spraying, preheating, soldering functions. The wave peak is stable and the maintenance is simple, mechanical pump and electromagnetic pump are optional.

It can be used for soldering by a single solder machine or double solder machines. The maximum width for board passing can reach 600 mm. More importantly, the machine is normally used for massive production application scenarios.

Integrated full-function model, there are three PCB boards or fixtures inside the machine at the same time working at the spraying, preheating and welding points, which improves the overall production capacity of the machine. Independent spray motion platform and independent welding motion platform.

Feature

1. Flux Spraying Module

- It adopts the original Germany imported spray head, with the opening diameter of 130μm.

- The spraying diameter can be as small as 3μm, which greatly reduces ion pollution.

- It can effectively save the using amount of scaling powder, the selective spraying saves at least 90% of flux compared with the traditional spraying.

- It is provided with a flux filter, which cam effectively prevent the spraying head from being blocked.

- The piezoelectric type injection valve and the micro scale type automation valve imported from Germany are optional.

- By adopting the X/Y dual-axis servo motor control, with the positioning precision reaching ±0.02mm.

2. Preheating Module

- Preheating is divided into independent temperature control in upper part and lower part: it adopts hot wind convection preheating on top, and short-wave infrared preheating on bottom, which increases heat efficiency, and meanwhile it ensures uniformity of temperature.

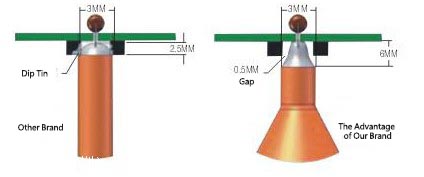

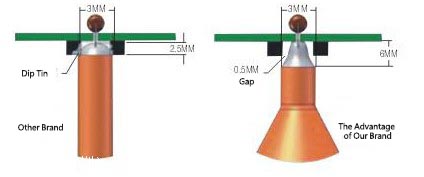

3. Soldering Module

- By adopting the patented Gauss tin soldering nozzles, it solves the problems of soldering when the devices are dense

3. Flexibility For Your SMT Assembly

- Adopted with modular design, it also compatible with SMEMA online connection, support customization for flexible line assembly. Full computer control, parameters are set and saved on the computer. Generating configuration files are easy for traceability and preservation.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

LED SMT Machines Line, SMT Production Line Solutions, SMT AutomatIC PCB Solder Paste Printing Machine, AutomatIC Stencil Printer, Best Reflow Oven, Vapor Phase Reflow Oven, Mini Wave Soldering Machine, PICk-And-Place Automation, Chip Mounter Equipment, Chip Mounter Desktop, Chip Mounter Feeder, PanasonIC Chip Mounter, Asm Chip Mounter, Eight Head Chip Mounter, PCB AutomatIC Coating Spraying Gluing Machine, Coating Spraying Gluing Machine PCB LED, Coating Spraying Gluing Machine PCB LED Display, PCB Board Cutting Machine For All Kinds, Low Cost Fpc PCB UV Laser Cutting Machine, V Cut SMT PCB Separator Cut Machine